Carbon brush holders, seemingly small components in the world of electric motors and generators, play a crucial role in ensuring machinery’s smooth and efficient operation across various industries. A high-quality carbon brush holder ensures proper alignment and contact between the brush and the commutator, facilitating uninterrupted electrical transmission and minimizing wear and tear. Making it essential to provide superior quality materials and promising craftsmanship by the side, the factors collectively contribute to the durability and reliability of the holder. It also helps reduce the risk of overall downtime and maintenance costs.

As one of the best carbon brush holder manufacturers, we at Hatim Carbon Company recognize the importance of brush holders and are dedicated to providing top-notch solutions that meet the rigorous demands of modern-day applications. Providing carbon brush holders that help with improved performance and longevity of the machinery, our range of carbon brush holders also ensures operations efficiency and productivity, making them crucial components in any motor or generator system’s carbon brush holder assembly.

From advanced motors to industrial generators, discover the ideal holder for your machine’s pinnacle performance – revolutionizing industry standards with expedited delivery.

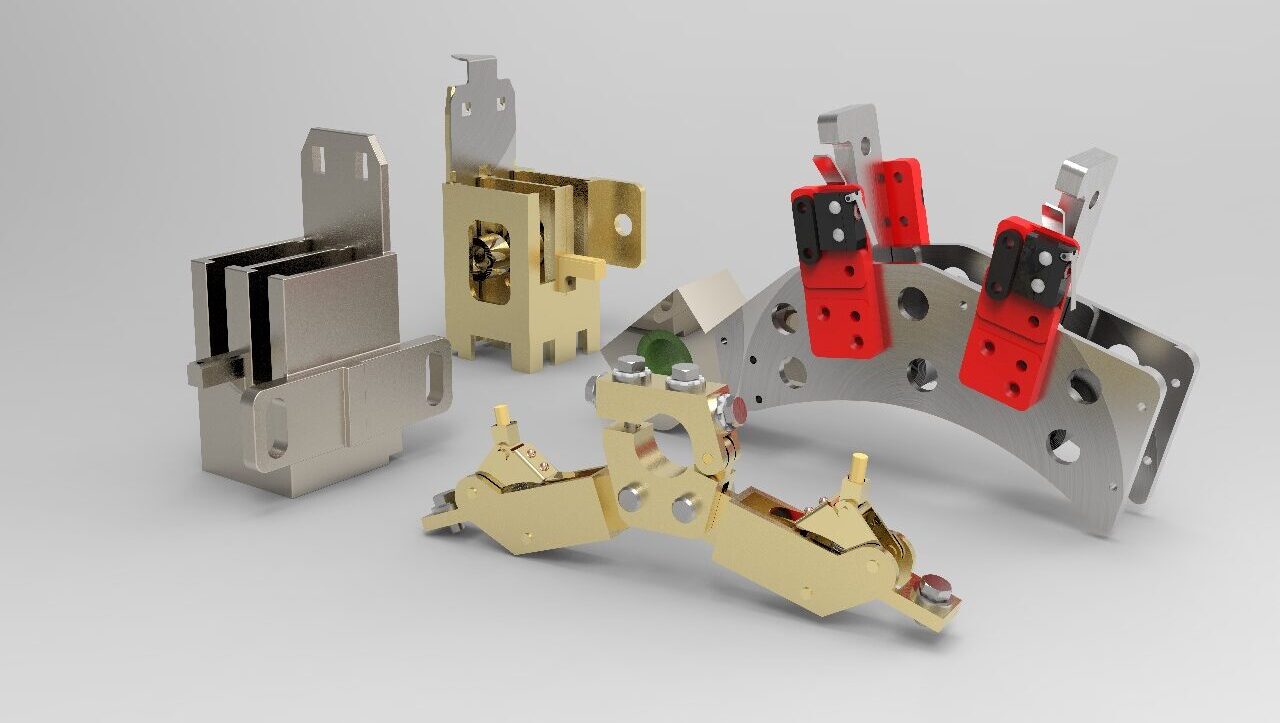

Excel in high-friction environments and vibratory applications. Engineered for stability and efficient electrical transfer, they ensure reliability in demanding conditions.

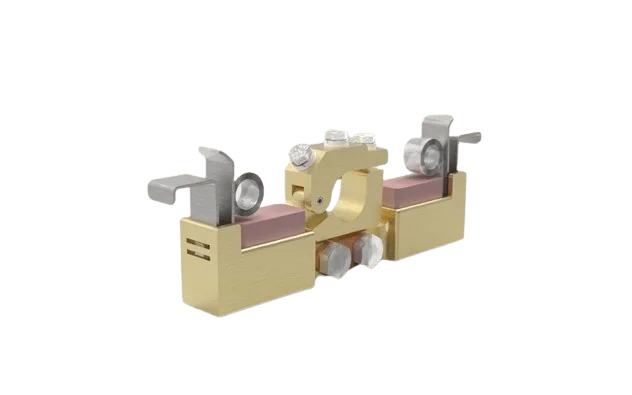

Ensure excellent commutation and spring pressure. Designed with precision, they guarantee reliable performance and optimal electrical transfer, even in demanding conditions.

Guaranteed precision in maintaining consistent pressure. Engineered for reliable performance, and ensure seamless electrical transfer in all applications.

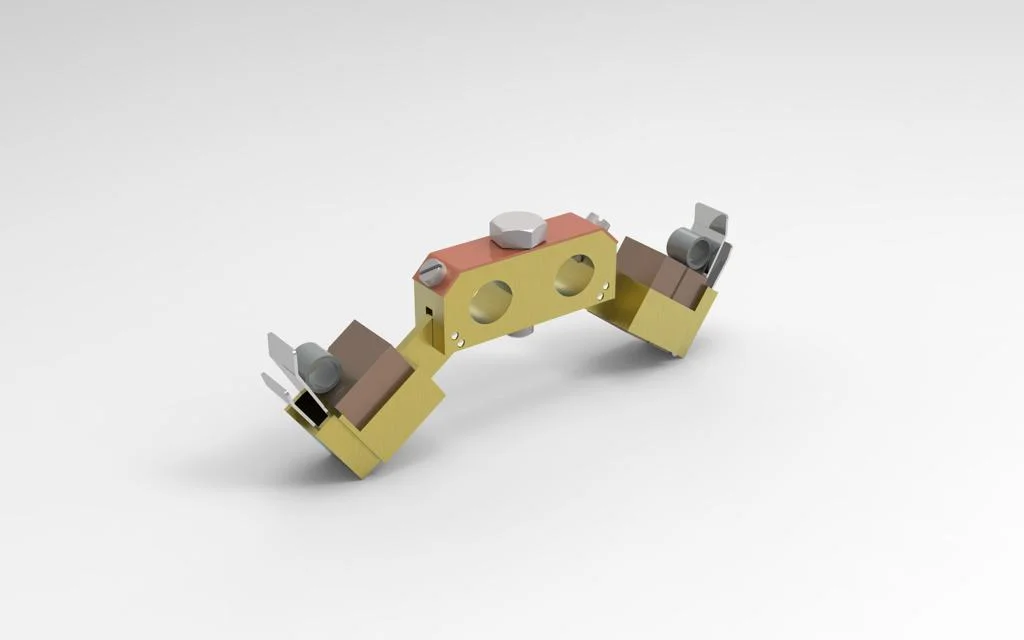

Perfect for high RPM and high vibration environments. Manufacture in stamped mechanism ensure that tolerances are consistent and maintained.

Consistent brush pressure in spring systems, and high-quality brass for electrical transfer in GRU applications. Feature insulatory support with ribbed G-10 material to avoid stray current or tracking.

Specially designed as per customer application for any environment according to requirement. After manufacturability assessment, is optimised for production with low turnaround times.

Our carbon brush holders boast several key features that set them apart in terms of performance, durability, and reliability:

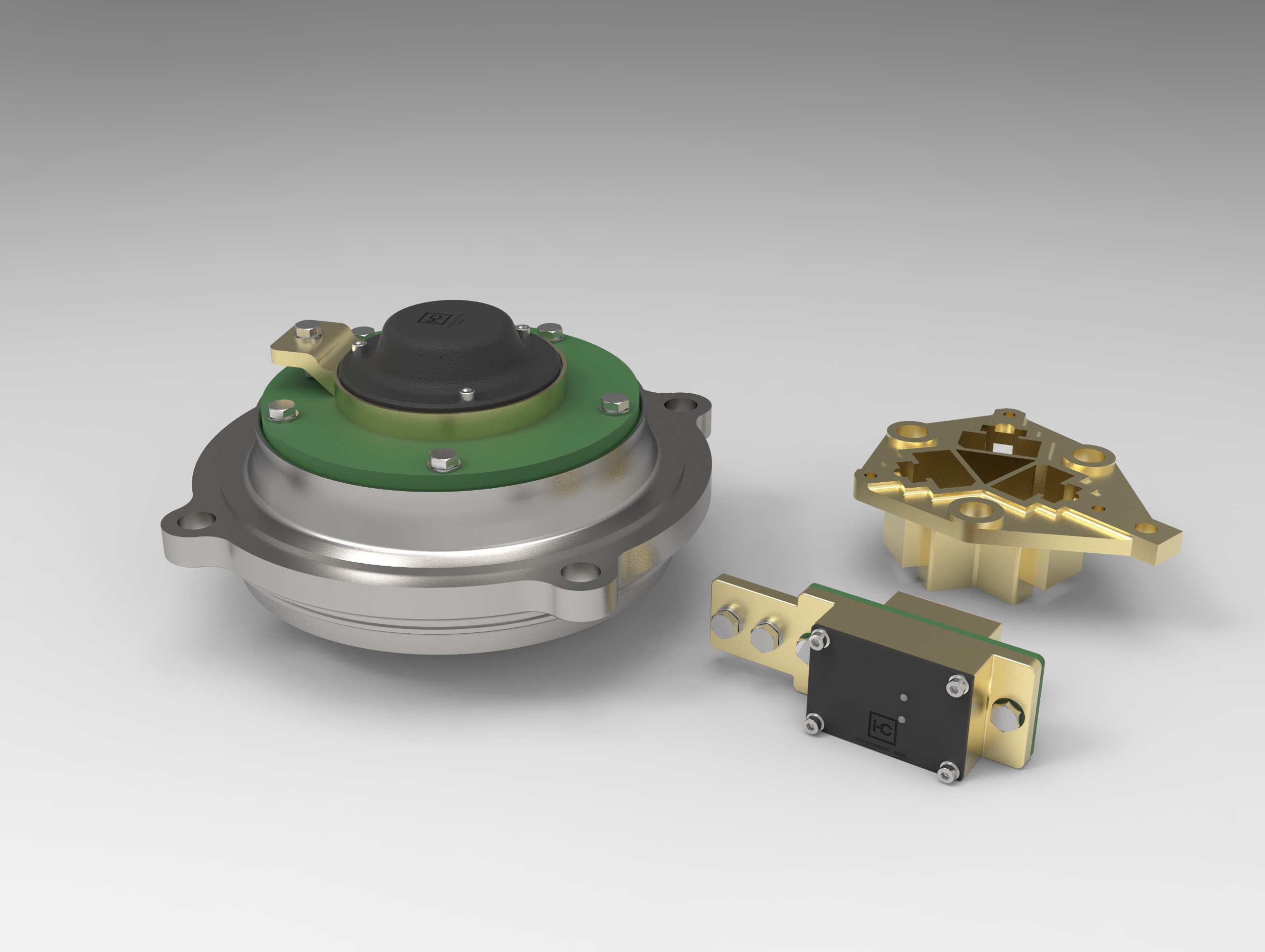

The brush holders, including the brass carbon brush holder, are specifically crafted with precision engineering techniques to ensure optimal alignment and contact between the carbon brush and the commutator. This precision is crucial for maintaining consistent electrical contact, minimizing wear on the brush and commutator, and maximizing electrical transmission efficiency within the motor or generator. Each carbon brush holder assembly component is carefully designed to meet exacting standards, ensuring reliable durability and functional efficiency.

Since high-quality materials are essential for the reliability of the carbon brush holder, brass, known for its excellent conductivity and corrosion resistance, is often chosen as the prime component of the brush holder assembly in demanding industrial environments. Carbon brush holder assemblies are engineered to withstand the rigors of continuous operation, resisting wear and tear over time to maintain consistent performance and minimize the need for frequent replacements.

Effective heat dissipation is crucial for preventing overheating and extending the service life of carbon brush holders. Brass carbon brush holders are designed to efficiently dissipate heat generated during operation, helping to maintain stable operating temperatures and prevent premature degradation of the brush and holder materials. By effectively managing heat buildup, carbon brush holders contribute to the overall efficiency, reliability and longevity of the motor or generator.

Carbon brush holders are often exposed to harsh operating conditions, leading to corrosion and degradation over time. To mitigate this risk, brass carbon brush holders are typically treated with corrosion-resistant coatings or alloys that enhance their durability and longevity. These protective measures ensure that the carbon brush holder assembly remains resilient in corrosive environments, preserving its functionality and reliability over the long term.

Carbon brush holders must withstand vibrations and mechanical stresses during operation without compromising electrical contact or stability. Brass carbon brush holders are engineered to absorb and dampen vibrations, maintaining consistent brush-to-commutator contact and minimizing the risk of electrical arcing or brush bounce. This vibration resistance ensures reliable performance and reduces the likelihood of premature wear or failure in high-vibration environments.

At Hatim Carbon Company, we pride ourselves on being more than just a manufacturer of carbon brush holders and ensuring quality brush holder assembly. We stand as your trusted partner in powering the machinery with precision and reliability. With decades of experience in the industry and a deep-rooted commitment to excellence, we have established ourselves as leaders in the industry, synonymous with expertise, cutting-edge technology, and quality assurance.

We offer customized solutions tailored to your specific needs including slipping, Carbo wind, carbon brush, etc, ensuring optimal performance and seamless integration. Our collaborative approach fosters partnerships that drive innovation and mutual success. With sustainability at our core, we ensure responsible manufacturing practices. Competitive pricing and our tech-backed support throughout the partnership certainly make us your trusted partner for all your carbon brush holder needs.

Partner with Hatim Carbon Company for Carbon Brush Holders and ensure precision and reliability, ensuring success every step of the way.

Our brush holders gain a competitive advantage through various proprietary processes and production methods. This not only sets us apart from the competition but also provides us with enhanced control over the performance aspects, ensuring unparalleled quality.

You cannot copy content of this page