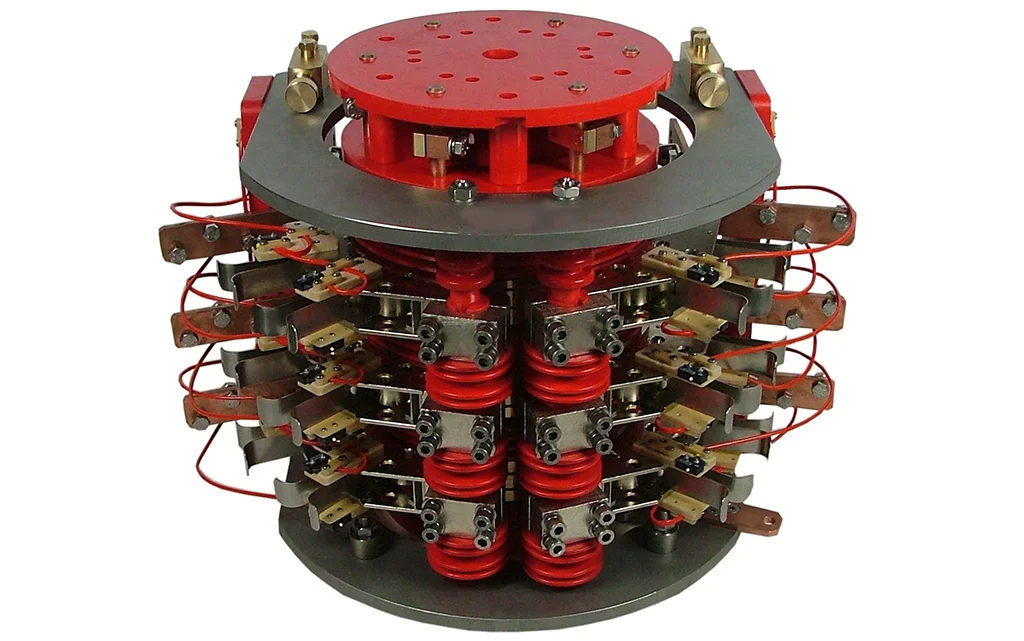

Slip ring units, commonly used in AC motors, serve as electromechanical devices that allows transmission of power and electrical signals between stationary and rotating structures. Consisting primarily of stainless steel or phosphor bronze rings, these units ensure optimal contact between the ring and stationary brushes to transfer electrical energy. With years of experience, Hatim Carbon specializes in making slip ring assemblies that bring convenience and safety to the operation of motors and generators.

Our stocks of sliprings are from the finest of slipring manufacturers around the globe for a variety of applications to cater to your specific needs.

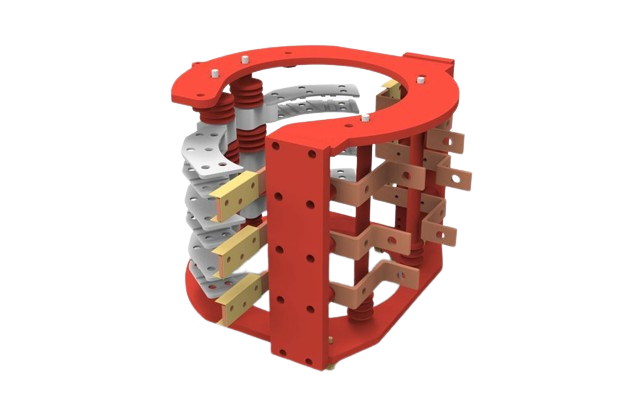

Enhance generator performance with our precision-engineered sliprings, ensuring seamless power transfer, minimal electrical noise, and extended durability. For reliable, efficient, and versatile solutions.

Designed to provide a stable and continuous flow of electrical power to the rotor, ensuring smooth and controlled motor operation. For industrial machinery, appliances, and automotive systems.

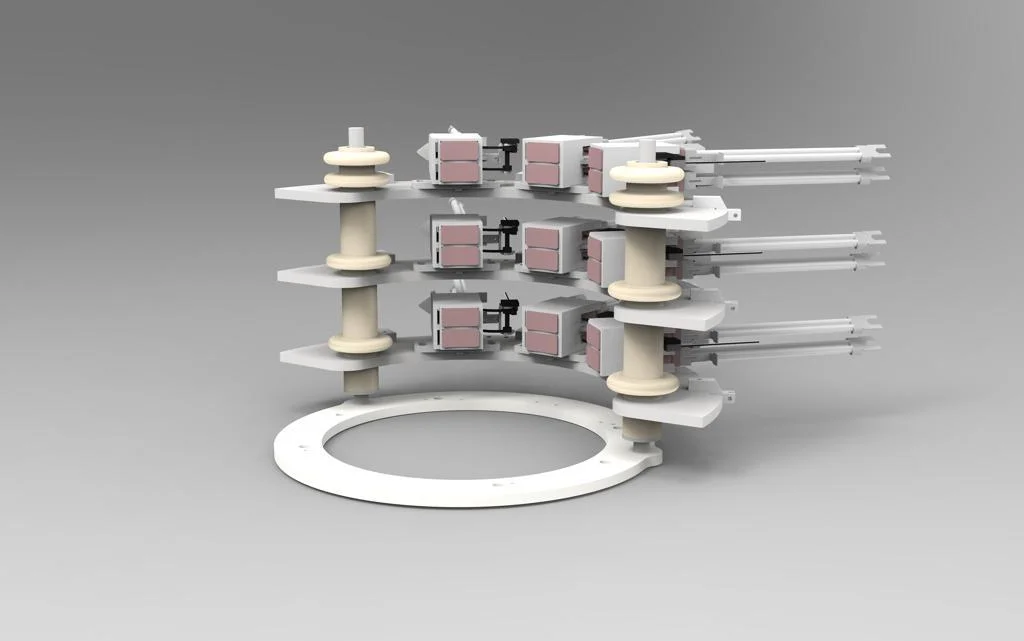

Ensure robust power transfer with our rocker assemblies, meticulously designed for secure brush holder placement. Enduring reliability in every electrical connection.

Fundamentally speaking, slip rings create room for mechanical efficiency, streamline system functionality, and eliminate the risk of damage from exposed wires on moving joints. However, Hatim distinguishes itself in the industry as a reliable Slip Ring Manufacturer by engineering slip rings that adeptly address the following challenges associated with a generator’s rotor:

Slip rings provide a reliable electrical connection between the stationary and rotating parts of machinery, allowing the transmission of power, signals, or data without interruption, even as the rotating component turns continuously.

In applications where continuous rotation is required, such as in wind turbines, cranes, or rotating stages in theaters, slip rings enable the rotation of equipment.

Slip rings facilitate the transmission of electrical signals or data between stationary and rotating components in applications such as surveillance cameras, radar systems, or medical imaging equipment.

In machinery with rotating parts, such as motors or generators, slip rings enable the transfer of electrical power from a stationary power source to the rotating equipment, ensuring continuous operation without the need for batteries or other temporary power sources.

Strategic planning and stocking of several components help us deliver sliprings in low lead times.

You cannot copy content of this page